Maglev Turbo Blower

Maglev Turbo Blower Introduction:

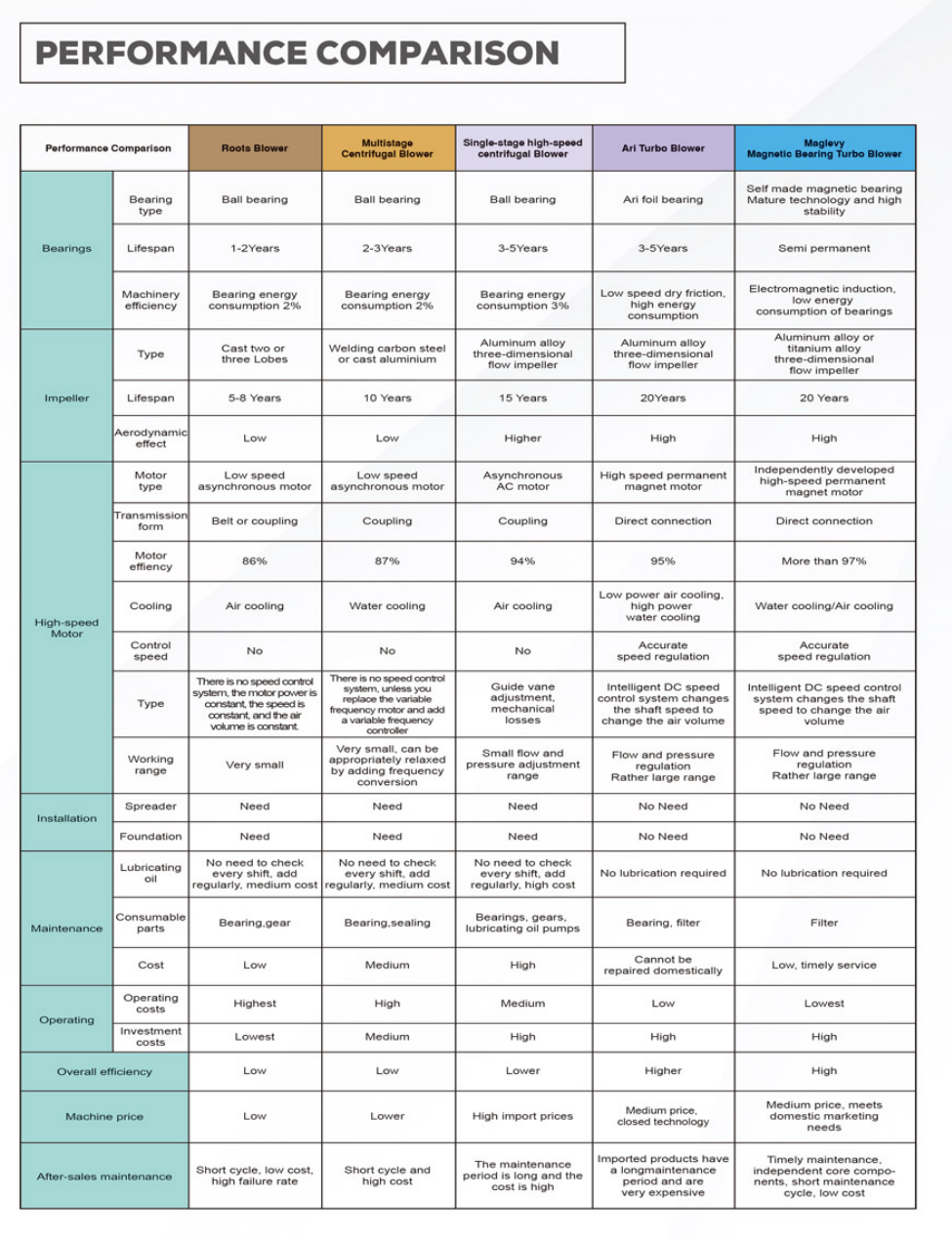

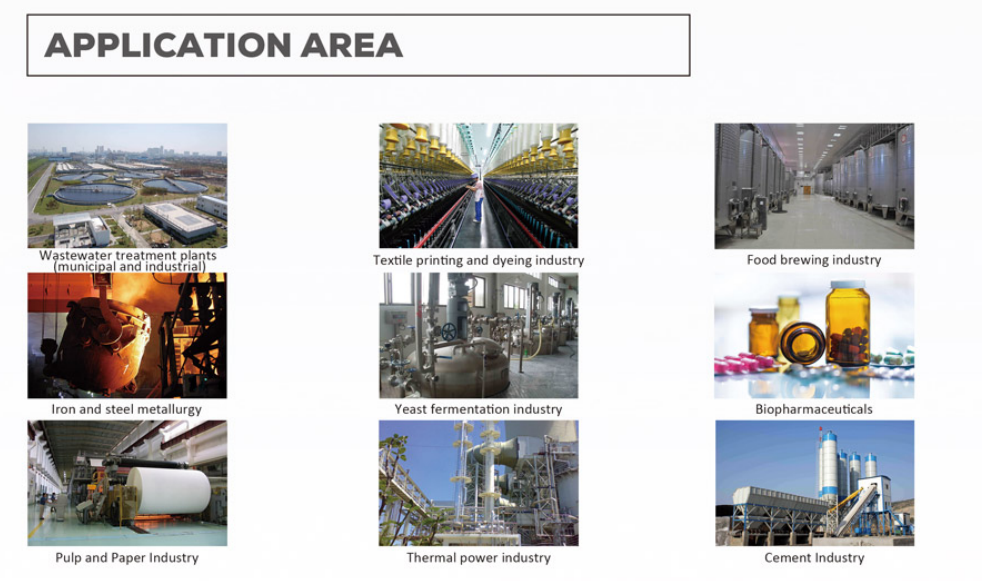

Maglev Turbo blower is a new type of centrifugal blower based on magnetic levitation bearing technology. They achieve contactless suspension operation of the rotor through electromagnetic force, completely eliminating mechanical friction. They offer advantages such as high efficiency, energy saving, torann íseal, and long service life. Compared with traditional positive displacement Roots blowers, their efficiency can be increased by 30%. They have been widely used in various industries, including backwashing, ash silo gasification, sewage aeration, municipal wastewater treatment, aquaculture oxygenation, desulfurization oxidation, petrochemicals, steel, cement, metallurgy, power generation, and food fermentation, gradually replacing traditional Roots blowers and ordinary centrifugal blowers.

Working Principle of Magnetic Levitation Turbo Blowers:

They primarily rely on magnetic levitation bearing technology and high-speed motor drive. This type of blower is directly driven by a high-speed motor, and the speed is controlled by a frequency converter. The key components include an active magnetic levitation bearing system and controllable electromagnetic force, which work together to achieve contactless, wear-free suspension support of the internal rotating magnetic levitation bearing. The magnetic levitation bearing is directly connected to the impeller, resulting in zero transmission loss, thus achieving successful gas delivery with no internal wear, torann íseal, and no lubrication required.

Shandong Mingtian Group Maglev Turbo Blower Core Technology:

① High-Efficiency Centrifugal Impeller

Designed using three-dimensional flow theory, maximizing impeller efficiency and providing a wide operating range. The centrifugal impeller is made of high-strength forged aluminum, with strong deformation resistance, and is precisely machined by a five-axis CNC machining center. The impeller surface is treated with hafnium oxide anodizing to enhance its corrosion resistance, resulting in less wear during long-term high-speed operation.

② Five-Degree-of-Freedom Magnetic Levitation Bearing

The company holds a patent for 12-level radial magnetic bearing technology. The magnetic levitation bearing uses controllable electromagnetic attraction to stably suspend the rotating shaft. During rotation, the shaft has no mechanical contact or friction, thus achieving high efficiency. There are no speed-increasing gears or oil-lubricated bearings, and no lubricating oil is required, resulting in oil-free air output.

③ Dedicated Control System

Equipped with a high-power variable frequency speed control system with complete independent intellectual property rights, the inverter boasts a measured efficiency (output power/input power) of up to 98%. It regulates motor speed by changing the output current frequency of the inverter, thereby adjusting the flow rate. It offers a wide operating range and automatically adjusts the motor speed according to the pipeline network conditions, enabling precise aeration. The motor control system, magnetic levitation control system, and overall machine control system are integrated into a single unit.

④ High-Power High-Speed Permanent Magnet Synchronous Motor

Utilizing a high-speed, high-power permanent magnet synchronous motor, made of samarium-cobalt magnet steel with a 42CrMoA shaft and H-class insulation, the motor is compact, lightweight, and features high power density and high rotational speed, reaching up to 60,000 rpm. It allows for stepless speed control. The motor rotor and impeller are directly coupled, resulting in low operating failure rate and high transmission efficiency.

⑤ Self-Generating System or UPS Power Supply

In the event of an unexpected power outage, the motor switches to “generation” mode. The rotor continues to rotate at high speed due to inertia, cutting the motor stator windings and converting kinetic energy into electrical energy. Simultaneously, the inverter switches to “rectification mode,” supplying the generated electricity to the “DC bus.” After conversion by the DC-DC converter, it continues to power the control system and magnetic levitation bearing controller until the rotor completely stops rotating and ceases generating electricity, preventing damage to the equipment caused by sudden power failure.

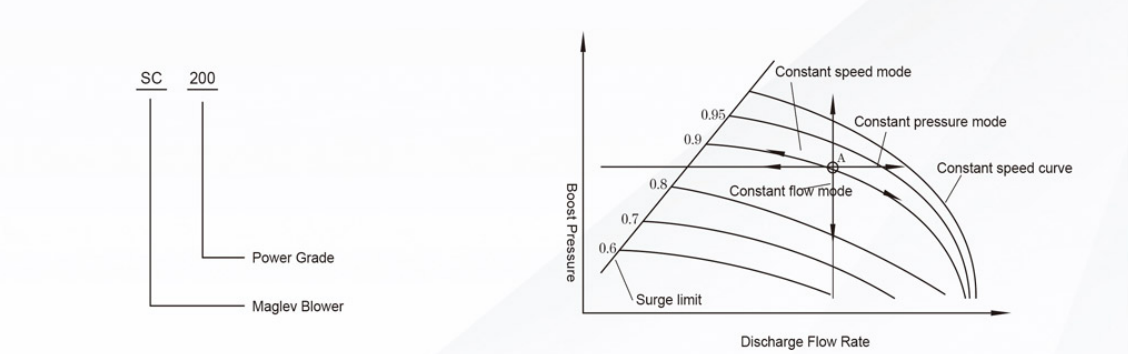

Model and Curve:

Specifications:

| Model | SC22 | SC30 | SC37 | SC45 | SC55 | SC75 | SC110 | SC150 | SC200 | SC250 | SC300 | SC350 | SC400 | SC500 | SC630 |

| △Pressure | Air Flow(m3/i):1.0 ATM,20℃ | ||||||||||||||

| 30 | 20 | 35 | 43 | 68 | 82 | 108 | |||||||||

| 40 | 17 | 32 | 38 | 52 | 66 | 93 | 123 | 180 | 235 | ||||||

| 50 | 15 | 24 | 35 | 44 | 50 | 71 | 103 | 152 | 190 | 255 | 290 | 375 | 390 | ||

| 60 | 13 | 21 | 32 | 37 | 48 | 65 | 88 | 130 | 173 | 217 | 260 | 320 | 330 | 450 | 572 |

| 70 | 10 | 19 | 27 | 32 | 40 | 54 | 78 | 114 | 155 | 192 | 235 | 280 | 290 | 400 | 500 |

| 80 | 17 | 25 | 29 | 36 | 51 | 73 | 100 | 133 | 167 | 200 | 250 | 255 | 352 | 434 | |

| 90 | 15 | 23 | 26 | 33 | 46 | 63 | 92 | 122 | 158 | 185 | 222 | 240 | 321 | 394 | |

| 100 | 30 | 42 | 59 | 85 | 115 | 142 | 170 | 198 | 220 | 290 | 364 | ||||

| 110 | 27 | 41 | 56 | 79 | 106 | 136 | 162 | 191 | 215 | 272 | 334 | ||||

| 120 | 25 | 38 | 52 | 74 | 100 | 125 | 148 | 175 | 190 | 255 | 316 | ||||

| 130 | 35 | 49 | 69 | 96 | 119 | 142 | 167 | 190 | 241 | 292 | |||||

| 140 | 32 | 47 | 63 | 92 | 112 | 136 | 160 | 182 | 225 | 283 | |||||

| 150 | 30 | 44 | 60 | 90 | 105 | 128 | 150 | 175 | 210 | 267 | |||||

| Blower Type | Sé séidire fréamhacha | Maglev Turbo Blower |

| Brand | Maglev | |

| Blower Model | / | SC110 |

| Qty | 1 | 1 |

| △Pressure(KPA) | 70 | 70 |

| Air Flow(m3/i) | 70 | 70 |

| Installed Power(kw) | 185 | 110 |

| Operation Power(kw) | 125 | 85.7 |

| Blower saving power(kw) | 125-85.7=39.3 | |

| Energy saving ratio | 39.3/125=31.4% | |

| Annual Energy saving power | 39.3*8600=337980 | |

| Annual Energy saving cost(0.118usd/kw·h) | 337980*0.118=39881.64usd | |

| Annual Comprehensive Econonmic Benefit | 39881.64usd | |

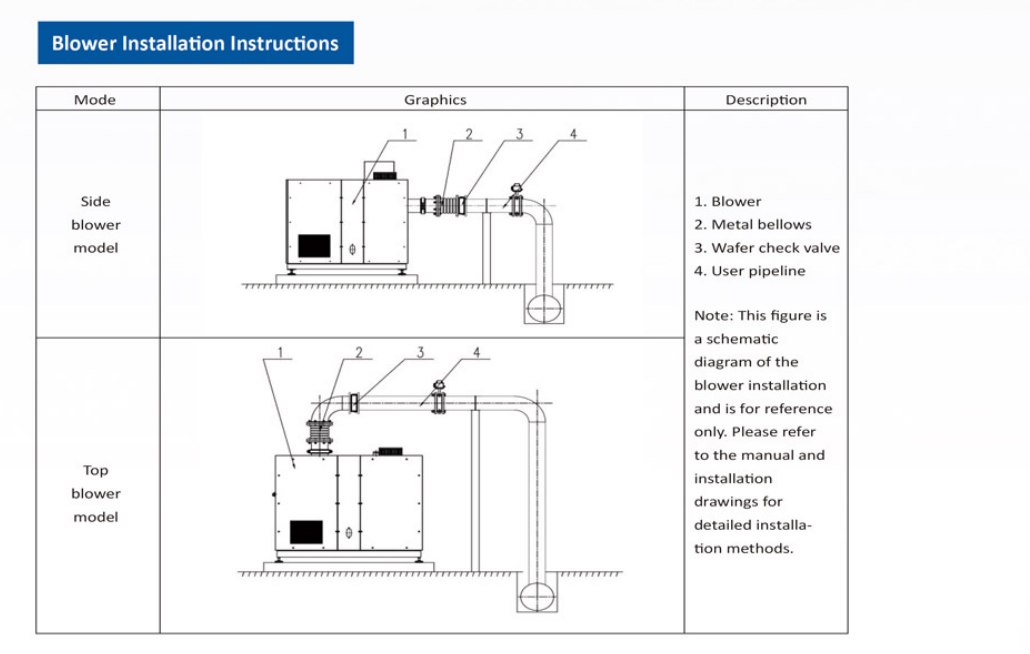

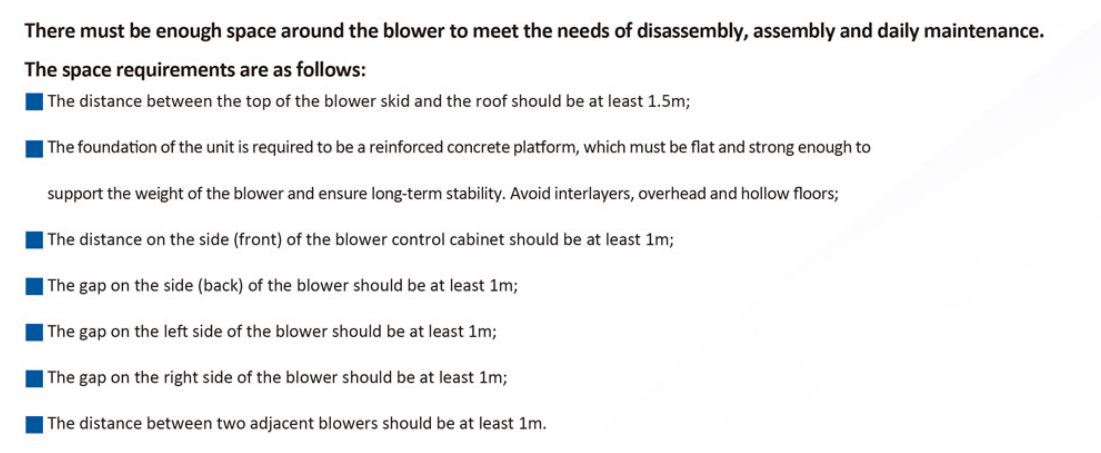

Installation:

Quality Assurance:

To strengthen quality management and strive for excellence in quality, our company, guided by the principle of “providing customers with satisfactory products and comprehensive services,” solemnly promises our esteemed customers:

(1) We will strictly establish, maintain, and implement a product quality assurance system in accordance with ISO9001 quality management and quality assurance standards, and promptly provide customers with reliable and qualified products.

(2) We guarantee that the equipment is brand new, of excellent quality, with advanced and reasonable design, free from defects in materials and workmanship, and without any quantity shortages.

(3) We will provide technical training according to customer needs, establish quality communication with customers, and implement follow-up services.

(4) When our company’s product technical software is updated, we promise to provide free technical software upgrades for the fans purchased by your company.

After-Sales Service:

To better ensure the normal operation of the equipment, promptly answer customer questions, and help customers solve problems, our company’s maintenance center and regional maintenance points are responsible for services such as commissioning, maintenance, and technical consultation in various regions. The maintenance center is staffed by dedicated engineers who provide free consulting services to customers at any time. We guarantee real-time telephone response and remote guidance within 2 hours in case of equipment failure. The company’s maintenance center provides 24-hour telephone service, with dedicated engineers handling customer calls to ensure that users receive timely technical support during the use of the equipment.

If you are interested in our maglev turbo blower product, welcome to contact us.

Comhstoic Ghrúpa Innealra Shandong Mingtian Co., Ltd., established in 2007, is located in Zhangqiu District, Cathair na Jinan, Cúige Shandong,tSín. With a total factory area of over 170 acra, it is a national high-tech enterprise integrating research and development, manufacturing, and sales. Its subsidiary, Shandong Maglev Energy Saving Technology Co., Ltd., primarily develops and manufactures various products including magnetic levitation bearings, high-speed permanent magnet synchronous motors, magnetic levitation single-cantilever centrifugal blowers, and magnetic levitation bearing controllers. The company is committed to promoting the application of magnetic levitation technology in high-end centrifugal blowers, high-end centrifugal compressors, and high-power high-speed motors.