磁懸浮渦輪鼓風機

磁懸浮渦輪鼓風機 介紹:

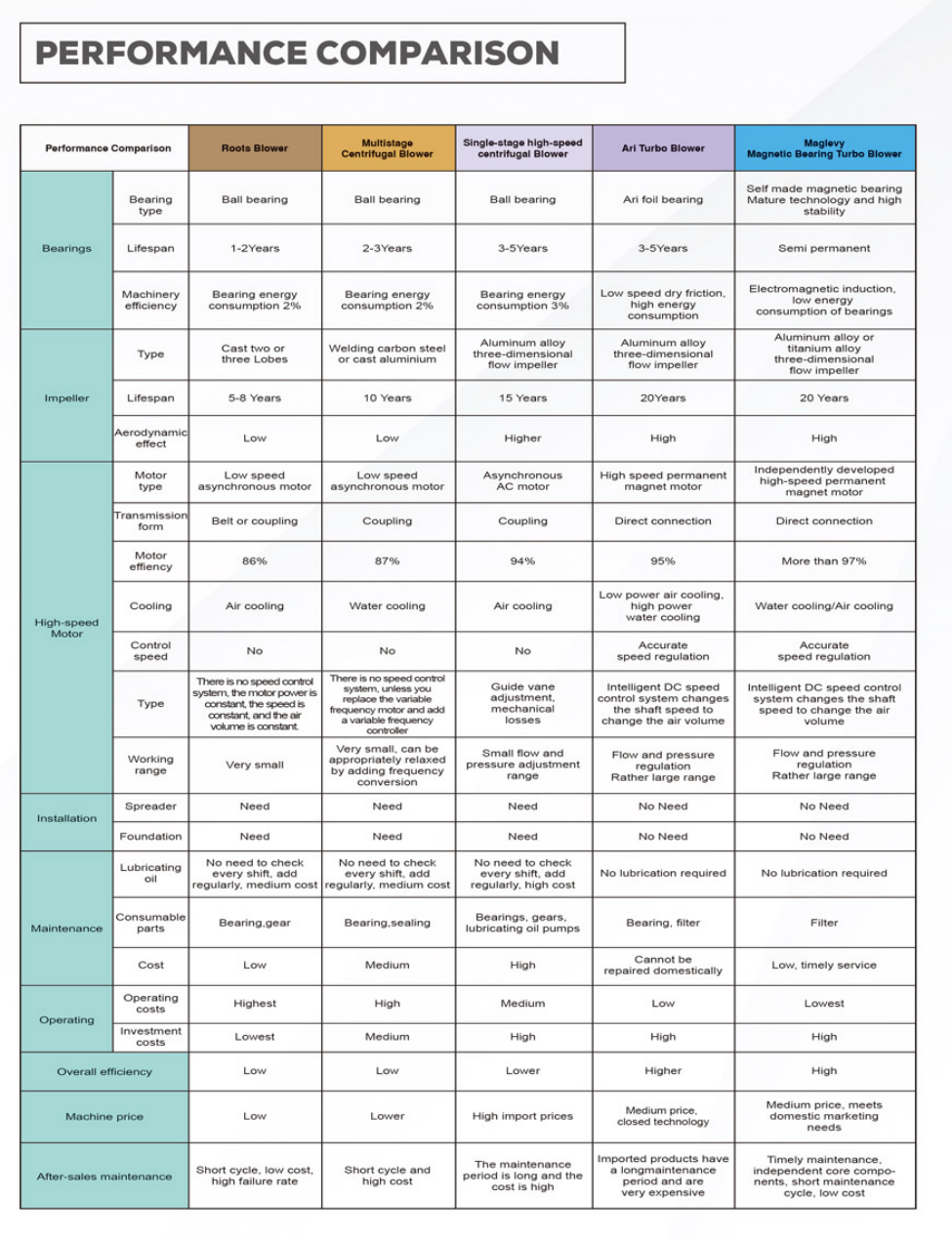

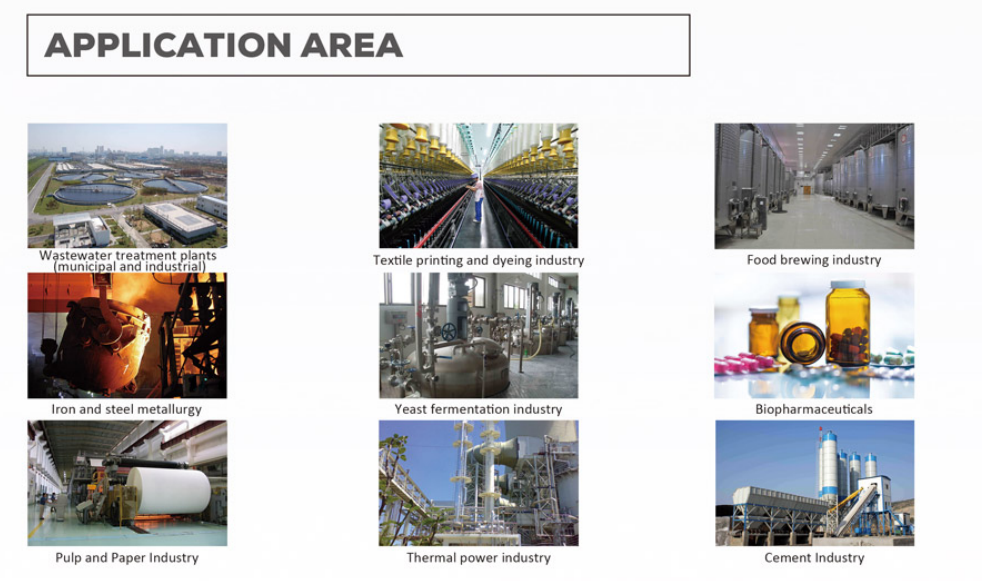

磁懸浮渦輪鼓風機是一種基於磁懸浮軸承技術的新型離心鼓風機. 它們通過電磁力實現轉子的非接觸懸浮操作, 完全消除機械摩擦. 它們具有高效率等優點, 節能, 低噪音, 使用壽命長. 與傳統容積式羅茨鼓風機相比, 他們的效率可以通過以下方式提高 30%. 它們已被廣泛應用於各個行業, 包括反洗, 灰倉氣化, 污水曝氣, 市政污水處理, 水產養殖增氧, 脫硫氧化, 石化產品, 鋼, 水泥, 冶金, 發電, 和食品發酵, 逐步取代傳統羅茨鼓風機和普通離心鼓風機.

磁懸浮渦輪鼓風機工作原理:

它們主要依靠磁懸浮軸承技術和高速電機驅動. 該型鼓風機由高速電機直接驅動, 速度由變頻器控制. 關鍵部件包括主動磁懸浮軸承系統和可控電磁力, 它們共同實現非接觸式, 內部旋轉磁懸浮軸承的無磨損懸浮支撐. 磁懸浮軸承直接與葉輪連接, 從而實現零傳輸損耗, 從而實現成功的氣體輸送且無內部磨損, 低噪音, 並且無需潤滑.

Shandong Mingtian Group 磁懸浮渦輪鼓風機 核心技術:

① 高效離心葉輪

採用三維流動理論設計, 最大限度地提高葉輪效率並提供廣泛的工作範圍. 離心葉輪採用高強度鍛鋁材質, 抗變形能力強, 並由五軸CNC加工中心精密加工. 葉輪表面經過氧化鉿陽極氧化處理,增強其耐腐蝕性能, 從而減少長期高速運行時的磨損.

② 五自由度磁懸浮軸承

公司持有12級徑向磁力軸承技術專利. 磁懸浮軸承利用可控電磁吸力穩定懸浮轉軸. 旋轉期間, 軸沒有機械接觸或摩擦, 從而實現高效率. 無增速齒輪或油潤滑軸承, 並且不需要潤滑油, 產生無油空氣輸出.

③ 專用控制系統

配備具有完全自主知識產權的大功率變頻調速系統, 該逆變器擁有可測量的效率 (輸出功率/輸入功率) 最多可達 98%. 通過改變變頻器輸出電流頻率來調節電機轉速, 從而調節流量. 運行範圍寬,可根據管網情況自動調節電機轉速, 實現精確通氣. 電動機控制系統, 磁懸浮控制系統, 和整個機器控制系統集成到一個單元中.

④ 大功率高速永磁同步電機

利用高速, 大功率永磁同步電機, 採用釤鈷磁鋼製成,軸為 42CrMoA,H 級絕緣, 電機結構緊湊, 輕的, 具有高功率密度和高轉速的特點, 達到 60,000 RPM. 它允許無級速度控制. 電機轉子與葉輪直接耦合, 運行故障率低,傳輸效率高.

⑤ 自發電系統或UPS電源

如果發生意外停電, 電機切換到 “一代” 模式. 轉子由於慣性繼續高速旋轉, 切割電機定子繞組並將動能轉換為電能. 同時地, 逆變器切換到 “整改模式,” 將產生的電力供應給 “直流母線。” 經過DC-DC轉換器轉換後, 它繼續為控制系統和磁懸浮軸承控制器供電,直到轉子完全停止旋轉並停止發電, 防止突然停電造成設備損壞.

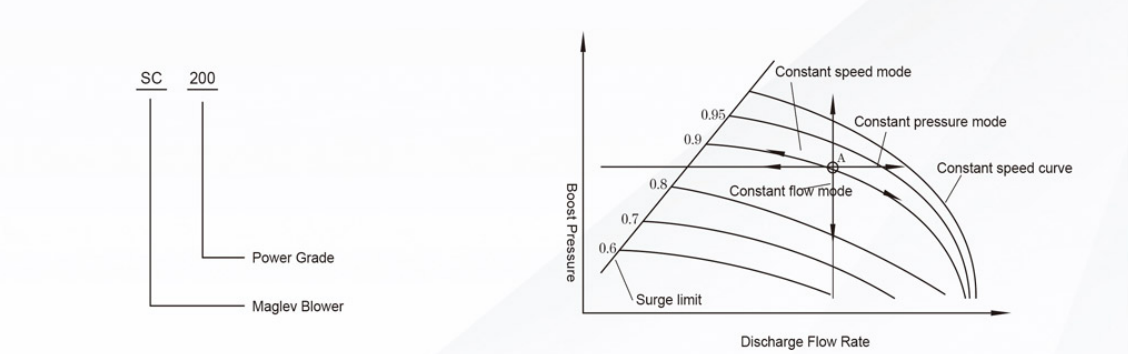

模型與曲線:

規格:

| 模型 | SC22 | SC30 | SC37 | SC45 | SC55 | SC75 | SC110 | SC150 | SC200 | SC250 | SC300 | SC350 | SC400 | SC500 | SC630 |

| △壓力 | 空氣流動(M3/i):1.0 ATM,20℃ | ||||||||||||||

| 30 | 20 | 35 | 43 | 68 | 82 | 108 | |||||||||

| 40 | 17 | 32 | 38 | 52 | 66 | 93 | 123 | 180 | 235 | ||||||

| 50 | 15 | 24 | 35 | 44 | 50 | 71 | 103 | 152 | 190 | 255 | 290 | 375 | 390 | ||

| 60 | 13 | 21 | 32 | 37 | 48 | 65 | 88 | 130 | 173 | 217 | 260 | 320 | 330 | 450 | 572 |

| 70 | 10 | 19 | 27 | 32 | 40 | 54 | 78 | 114 | 155 | 192 | 235 | 280 | 290 | 400 | 500 |

| 80 | 17 | 25 | 29 | 36 | 51 | 73 | 100 | 133 | 167 | 200 | 250 | 255 | 352 | 434 | |

| 90 | 15 | 23 | 26 | 33 | 46 | 63 | 92 | 122 | 158 | 185 | 222 | 240 | 321 | 394 | |

| 100 | 30 | 42 | 59 | 85 | 115 | 142 | 170 | 198 | 220 | 290 | 364 | ||||

| 110 | 27 | 41 | 56 | 79 | 106 | 136 | 162 | 191 | 215 | 272 | 334 | ||||

| 120 | 25 | 38 | 52 | 74 | 100 | 125 | 148 | 175 | 190 | 255 | 316 | ||||

| 130 | 35 | 49 | 69 | 96 | 119 | 142 | 167 | 190 | 241 | 292 | |||||

| 140 | 32 | 47 | 63 | 92 | 112 | 136 | 160 | 182 | 225 | 283 | |||||

| 150 | 30 | 44 | 60 | 90 | 105 | 128 | 150 | 175 | 210 | 267 | |||||

| 鼓風機類型 | 根鼓風機 | 磁懸浮渦輪鼓風機 |

| 品牌 | 磁浮 | |

| 鼓風機型號 | / | SC110 |

| 數量 | 1 | 1 |

| △壓力(KPA) | 70 | 70 |

| 空氣流動(M3/i) | 70 | 70 |

| 裝機功率(千瓦) | 185 | 110 |

| 操作電源(千瓦) | 125 | 85.7 |

| 鼓風機省電(千瓦) | 125-85.7=39.3 | |

| 節能率 | 39.3/125=31.4% | |

| 年節能電量 | 39.3*8600=337980 | |

| 年節能成本(0.118美元/千瓦·小時) | 337980*0.118=39881.64美元 | |

| 年度綜合經濟效益 | 39881.64美元 | |

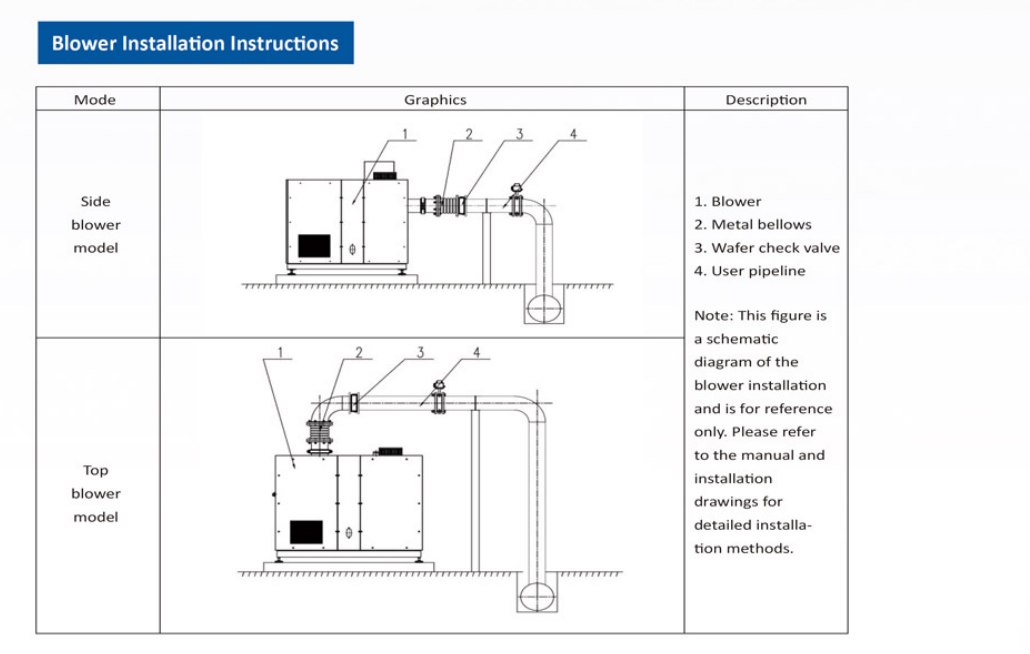

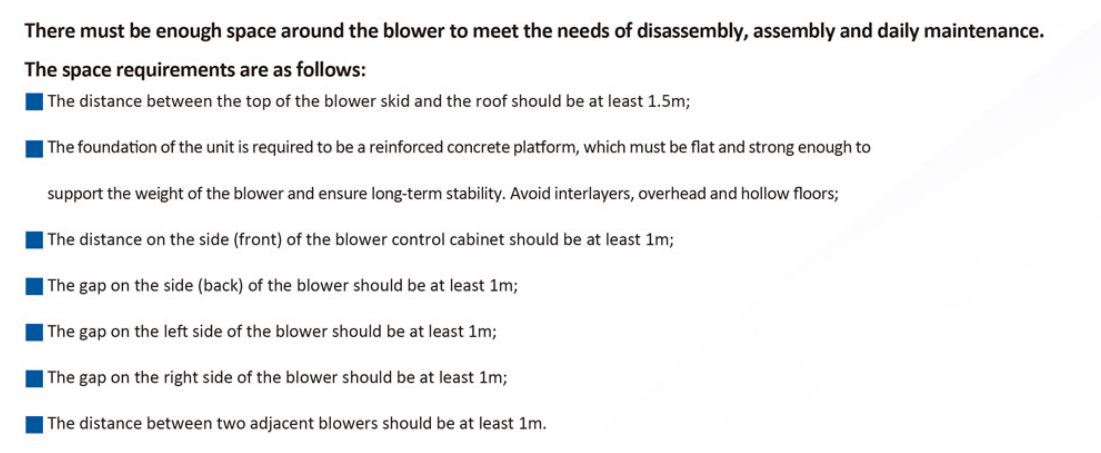

安裝:

品質保證:

強化質量管理,追求品質精益求精, 我們公司, 原則指導下 “為客戶提供滿意的產品和全面的服務,” 向尊敬的客戶鄭重承諾:

(1) 我們將嚴格建立, 維持, 並按照ISO9001質量管理和質量保證標準實施產品質量保證體系, 及時為客戶提供可靠、合格的產品.

(2) 我們保證設備全新, 品質優良, 設計先進合理, 無材料和工藝缺陷, 並且沒有任何數量短缺的情況.

(3) 我們將根據客戶需求提供技術培訓, 與客戶建立優質的溝通, 並落實後續服務.

(4) 當我公司產品技術軟件更新時, 我們承諾為貴公司購買的風機提供免費的技術軟件升級.

售後服務:

更好的保證設備的正常運行, 及時解答客戶問題, 並幫助客戶解決問題, 我公司維修中心及區域維修點負責調試等服務, 維護, 及各地區技術諮詢. 維修中心配備專職工程師,隨時為客戶提供免費諮詢服務. 我們保證實時電話響應和遠程指導 2 設備故障時的小時數. 公司維修中心提供24小時電話服務, 有專門的工程師處理客戶來電,確保用戶在設備使用過程中得到及時的技術支持.

如果您對我們的磁懸浮渦輪鼓風機產品感興趣, 歡迎聯繫我們.

山東明天機械集團股份有限公司, 有限公司, 成立於 2007, 位於章丘區, 濟南市, 山東省,中國. 工廠總面積超過 170 英畝, 是一家集研發、生產為一體的國家高新技術企業, 製造業, 和銷售. 其子公司, 山東磁浮節能科技有限公司, 有限公司, 主要研發和製造磁懸浮軸承等各類產品, 高速永磁同步電機, 磁懸浮單懸臂離心鼓風機, 和磁懸浮軸承控制器. 公司致力於推動磁懸浮技術在高端離心風機的應用, 高端離心壓縮機, 和大功率高速電機.