磁懸浮渦輪真空泵

磁懸浮渦輪真空泵 工作原理:

來自真空吸入點的空氣受到真空泵內高速旋轉的葉輪的作用, 將動能轉化為氣體壓力勢能, 產生負壓真空. 穿過蝸殼後, 以高溫空氣的形式排出.

磁懸浮渦輪真空泵 性能特點:

節能

採用主動磁懸浮軸承系統, 導致無磨損, 潤滑, 或維護要求. 高速永磁電機直接驅動立體流葉輪, 消除傳輸損耗. 永磁高速同步電機效率高達 98%. 它節省了超過 40% 與水環真空泵的能量比較, 多於 20% 與多級離心真空泵相比, 以及超過 15% 與單級高速真空泵相比. 高速旋轉的三維流動葉輪將動能轉化為氣體壓力勢能, 無需工作流體即可產生負壓真空.

安靜、低噪音

運行噪音低於 85 分貝(一個). 採用自平衡技術; 磁懸浮軸承的振動比傳統軸承小一個數量級. 安全無摩擦的操作, 無齒輪嚙合噪音. 採用主動減振設計, 從而降低機器振動.

智能便捷

採用高性能變頻器控制轉速, 具有多種控制模式可供選擇. 智能控制系統實時監控真空泵運行狀態, 集成防浪湧系統,確保安全穩定運行. 配備輔助軸承和斷電自發電系統,防止意外斷電造成設備損壞. 具有防浪湧和過載保護功能.

安裝方便,免維護

採用一體化緊湊設計, 需要最小的空間和簡單的佈局. 一鍵啟動和停止,安裝方便. 日常運行期間無需機械維護, 僅清洗過濾板.

磁懸浮渦輪真空泵技術參數:

| SCV磁懸浮渦輪真空泵 | ||||||||

| 模型 | SC55V | SC75V | SC110V | SC132V | SC150V | SC200V | SC250V | SC315V |

| 額定功率(千瓦) | 55 | 75 | 110 | 132 | 150 | 200 | 250 | 300 |

| 額定速度(轉速) | 35000 | 30000 | 27000 | 26000 | 20000 | |||

| 電壓(V) | 380 | |||||||

| 電纜規格 | 3*70+35 | 3*120+50 | 3*150+70 | 3*185+95 | 2*(3*150+1*90) | |||

| 噪音水平(分貝) | <80 | ≤85 | ||||||

| 吸力口徑(毫米) | 通徑200 | DN250 | DN300 | |||||

| 冷卻方式 | 水冷 | |||||||

| 佈局 | 分離式 | |||||||

| 重量(千克) | 900 | 1100 | 1600 | 2200 | 2600 | |||

| 真空度(KPA) | 體積流量(m3/最小),1.0 ATM, 35℃ | |||||||

| 20 | 123 | 168 | 246 | 290 | 335 | 447 | 558 | 670 |

| 25 | 110 | 150 | 220 | 260 | 300 | 400 | 500 | 600 |

| 30 | 88 | 120 | 176 | 208 | 240 | 320 | 400 | 480 |

| 35 | 84 | 115 | 169 | 199 | 230 | 307 | 383 | 460 |

| 40 | 71 | 96 | 141 | 167 | 193 | 257 | 321 | 385 |

| 45 | 70 | 95 | 139 | 165 | 190 | 253 | 317 | 380 |

| 50 | 62 | 85 | 125 | 147 | 170 | 227 | 283 | 340 |

| 55 | 61 | 84 | 123 | 145 | 168 | 223 | 279 | 335 |

| 60 | 60 | 82 | 121 | 143 | 165 | 219 | 275 | 330 |

| 65 | 59 | 80 | 119 | 141 | 163 | 214 | 271 | 325 |

| 70 | 58 | 79 | 117 | 139 | 160 | 210 | 267 | 320 |

| 80 | 如果真空壓力>70KPA,雙級真空泵將定制. | |||||||

| 90… | ||||||||

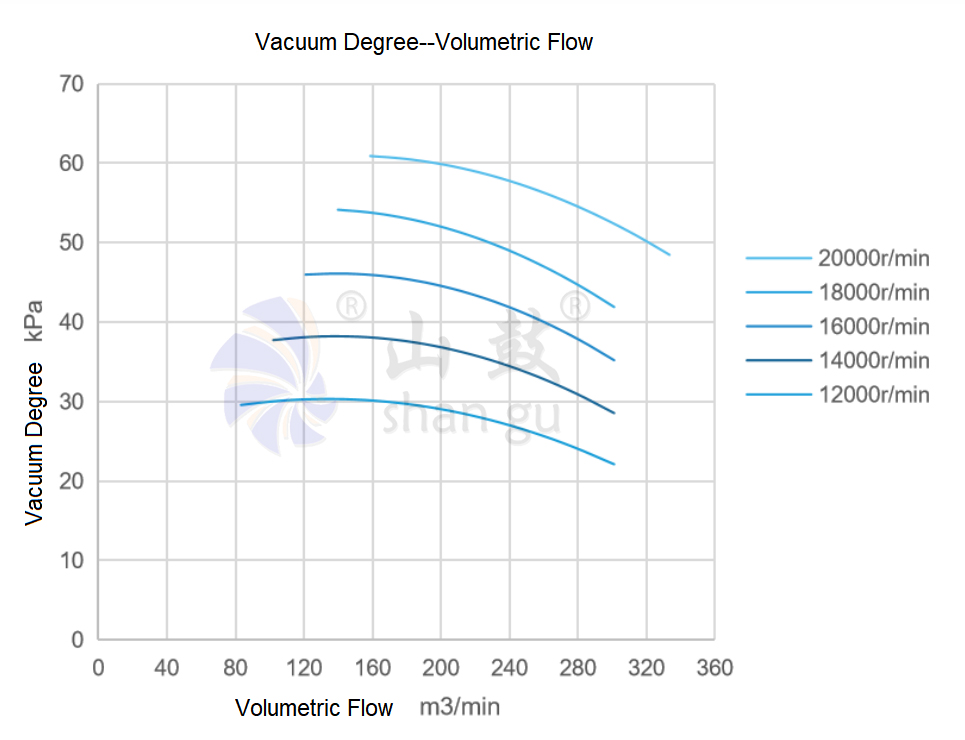

性能曲線:

項目現場:

磁懸浮渦輪真空泵 工作原理:

來自真空吸入點的空氣受到真空泵內高速旋轉的葉輪的作用, 將動能轉化為氣體壓力勢能, 產生負壓真空. 穿過蝸殼後, 以高溫空氣的形式排出.

特徵: 1.高效節能、高性能;2.安靜、低噪音;3.智能便捷;4.智能便捷

留言