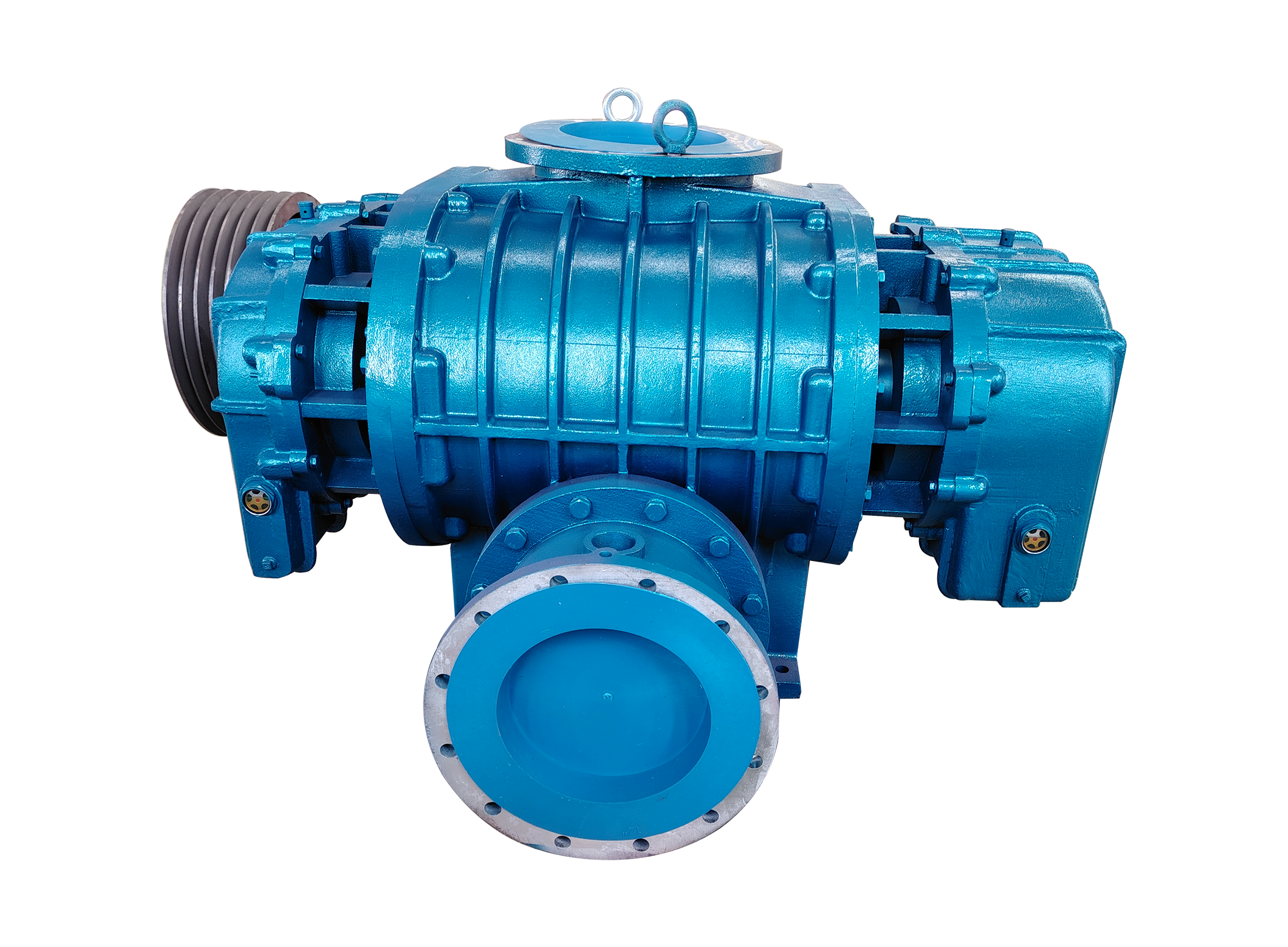

Three lobes roots blower

High Efficiency, Stability, Environmental Protection, and Energy Saving–Three-Lobe Roots Blower, the Reliable Choice for Industrial Pneumatic Conveying

Three lobes roots blower, In critical fields such as industrial pneumatic conveying, wastewater treatment, and petrochemicals, efficient and stable gas conveying equipment is essential to ensure continuous production and environmental compliance. Shandong Mingtian Machinery Group Co., Ltd. (hereinafter referred to as “Mingtian Machinery”), as a national high-tech enterprise, leverages its profound technological accumulation and innovative strength to launch its three-lobe Roots blower series products. With superior performance and energy-saving advantages, it has become the ideal choice for industry customers.

Product Core Advantages

High Efficiency and Stability, Low Energy Consumption Operation

The three lobes Roots blower adopts a three-lobe impeller design, resulting in smaller gas pulsation and lower noise compared to traditional two-lobe structures, while significantly improving volumetric efficiency. Optimized impeller curves and precision machining processes ensure stable airflow output, reducing energy loss and helping customers lower long-term operating costs.

Wide Flow and Pressure Range, Adaptable to Diverse Working Conditions

The flow rate covers 0.6~250 cubic meters/minute, and the pressure range is 9.8 kPa~98 kPa, allowing for flexible matching to various scenarios such as pneumatic conveying, wastewater treatment aeration, and chemical gas pressurization. Whether it’s powder material conveying or high-concentration wastewater treatment, it can provide stable power support.

Low Noise Design, Improved Working Environment

Through structural optimization and noise reduction technology, operating noise is effectively reduced, meeting modern industrial requirements for environmental protection and employee health, and is particularly suitable for factory environments sensitive to noise.

Robust and Durable, Easy Maintenance

The high-strength cast iron body and wear-resistant coating ensure long-term stable operation of the equipment under harsh working conditions. The modular design simplifies maintenance procedures, reduces downtime, and improves production efficiency.

Three lobes roots blower Specification

1.All models of RSR series roots blower

RSR-50 RSR-65 RSR-80 RSR-100 RSR-125 RSR-150C RSR-150 RSR-175A RSR-175 RSR-200 RSR-200H RSR-250D RSR-250 RSR-300 RSR-300C

2.Size of Discharge Bore

50(2″)、65(2.5″)、80(3.15″)、100(4″)、125(5″)、150(6″)、200(7.8″)、250(9.85″)、300(11.8″)

Or in customer’s indication range

3.Differential pressure scope

9.8—98kPa

4.Air capacity scope

0.6—184m3/min

5.Power of the motor

0.75—280kW

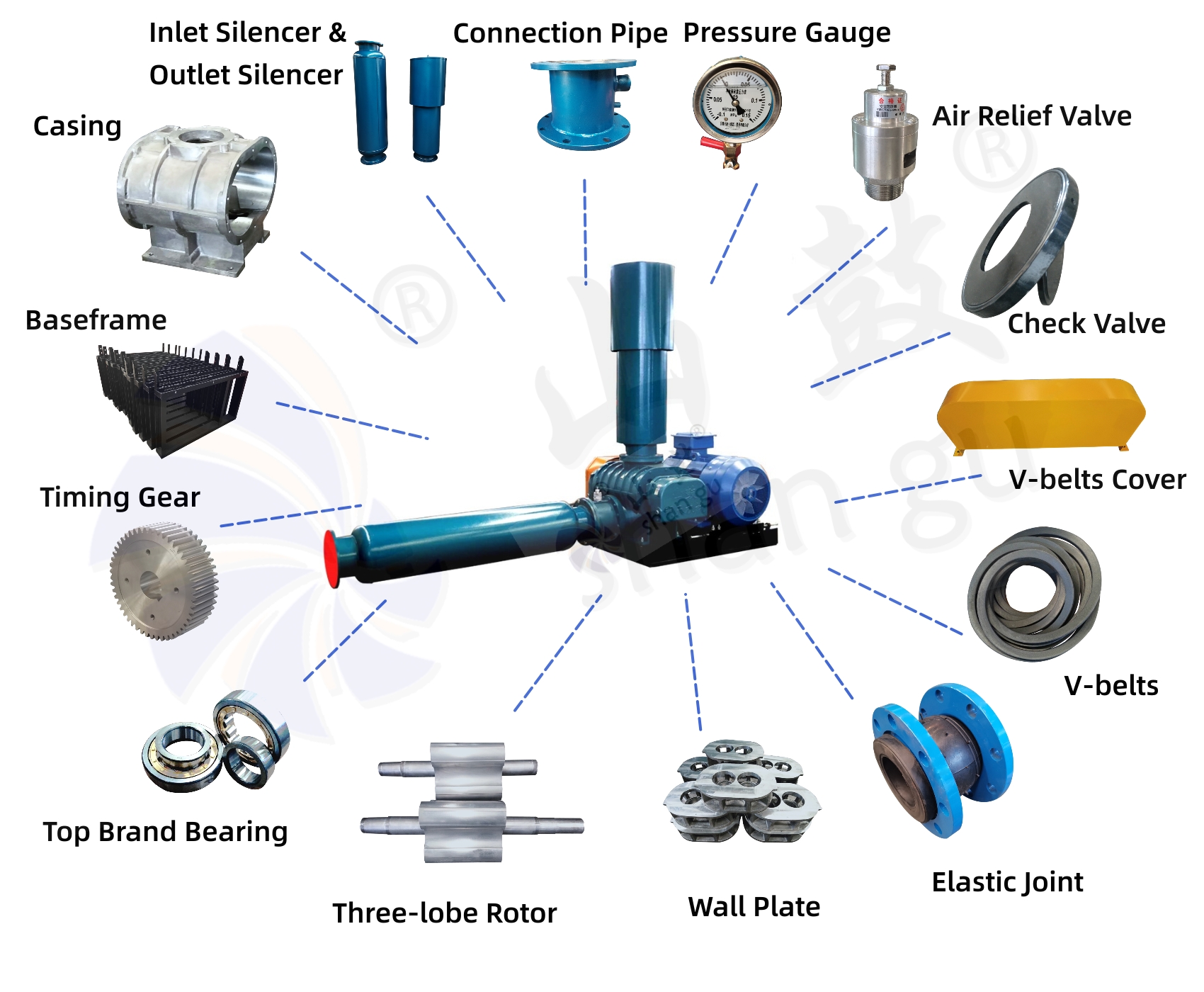

Necessary standard accessories(common type)

discharge connection pipe;suction silencer(with air filter) ,discharge silencer;flexible connector; check valve; anchor bolts; deflating valve; pressure gauge; baseframe ;gear oil,etc

Three lobes roots blower Application Scenarios

Pneumatic Conveying Systems: Providing efficient powder material conveying solutions for industries such as grain, chemicals, and building materials, avoiding dust pollution.

Wastewater Treatment Aeration: Ensuring uniform oxygen distribution in aeration tanks in municipal and industrial wastewater treatment, improving biochemical treatment efficiency.

Petrochemical Processes: Supporting gas pressurization and circulation, meeting process requirements such as reactor gas supply and gas recovery. Other industrial fields: such as power generation, metallurgy, and food processing, benefit from reliable air source support.

Three lobes roots blower technical highlights

Patented Impeller Design: The three-lobe impeller structure reduces airflow impact, improves volumetric efficiency, and lowers energy consumption.

Precision Manufacturing Process: High-precision CNC machining ensures uniform impeller clearance, reduces leakage, and extends service life.

Intelligent Monitoring Options: Pressure and temperature sensors can be integrated to provide real-time feedback on operating status, facilitating remote management.

Why Choose Mingtian Machinery?

National-Level Certification: As a specialized and innovative “Little Giant” enterprise, we offer dual guarantees of technological strength and product quality.

Full Product Range: We offer a variety of models, including RSR (low noise), MTR (high pressure), and MJ (compact), to meet customized needs.

Environmental Commitment: Our product design focuses on energy efficiency and emission control, helping customers achieve green production goals.

By choosing the three-lobe Roots blower, you will gain:

Significant Energy Savings: Reduce electricity costs and improve return on investment.

Stable Operation: Reduce downtime and ensure production continuity.

Environmental Compliance: Low noise and high efficiency design easily meet environmental regulations.

High Efficiency and Stability, Low Energy Consumption Operation

The three lobes Roots blower adopts a three-lobe impeller design, resulting in smaller gas pulsation and lower noise compared to traditional two-lobe structures, while significantly improving volumetric efficiency. Optimized impeller curves and precision machining processes ensure stable airflow output, reducing energy loss and helping customers lower long-term operating costs.

Wide Flow and Pressure Range, Adaptable to Diverse Working Conditions

The flow rate covers 0.6~250 cubic meters/minute, and the pressure range is 9.8 kPa~98 kPa, allowing for flexible matching to various scenarios such as pneumatic conveying, wastewater treatment aeration, and chemical gas pressurization. Whether it’s powder material conveying or high-concentration wastewater treatment, it can provide stable power support.

Low Noise Design, Improved Working Environment

Through structural optimization and noise reduction technology, operating noise is effectively reduced, meeting modern industrial requirements for environmental protection and employee health, and is particularly suitable for factory environments sensitive to noise.

Robust and Durable, Easy Maintenance

The high-strength cast iron body and wear-resistant coating ensure long-term stable operation of the equipment under harsh working conditions. The modular design simplifies maintenance procedures, reduces downtime, and improves production efficiency.