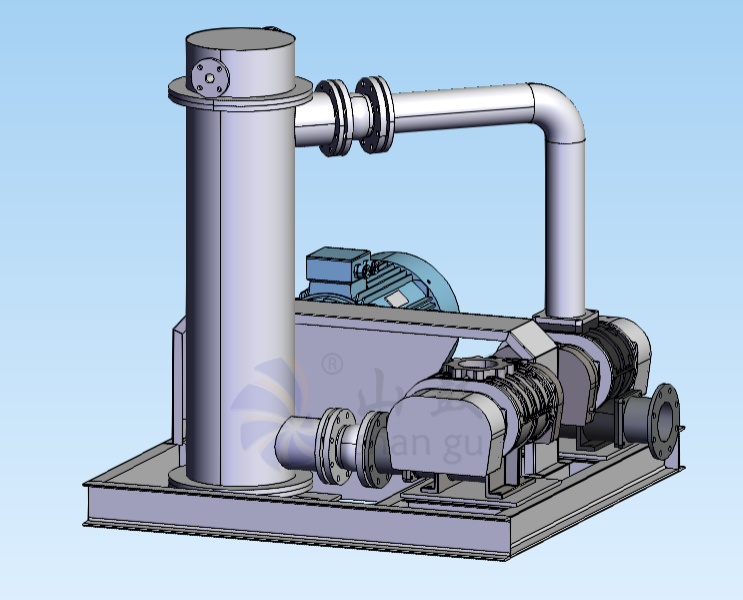

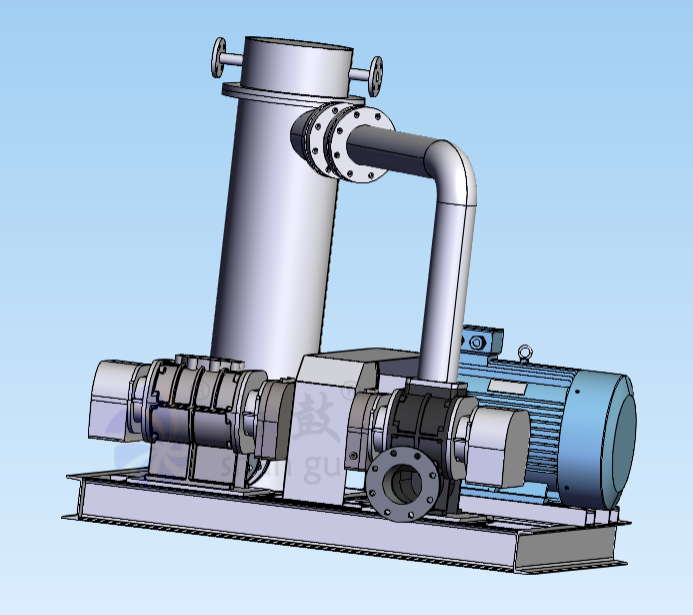

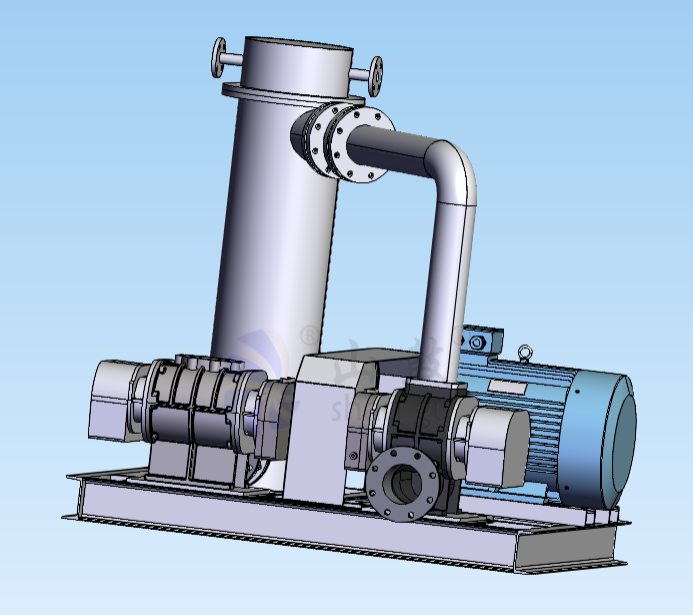

Double stage roots blower

Double stage roots blower: Due to factors such as efficiency and temperature rise, the pressure ratio of single-stage blowers is generally limited to 2.2. To achieve a higher pressure ratio, two blowers are often connected in series to form a double-stage series roots blower. In this configuration, double stage roots blower operation features an middle cooler between the two stages.

Double stage roots blower as an air conveying device, its characteristics mainly include the following aspects:

1.Through two-stage compression, it is possible to achieve higher exhaust pressure at a lower pressure ratio, making it suitable for industrial applications requiring higher air pressure.

2.The unique design of the Roots blower ensures continuous, pulse-free gas flow, maintaining stable flow rates under various operating conditions.

3.Due to the adoption of a simple mechanical structure and fewer moving parts, it experiences less wear during operation, requires lower maintenance, and enhances the equipment’s reliability and service life.

4.Compared to single-stage fans, the two-stage series design achieves the same air pressure with lower rotational speed, thereby reducing energy consumption and noise emissions, meeting modern industrial requirements for energy efficiency and environmental protection.

5.Suitable for various industries such as wastewater treatment, cement production, pneumatic conveying, chemical processing, and grain processing, providing stable gas delivery and pressure control for production processes in these sectors.

6.Despite being a dual-stage design, the overall structure remains compact through optimized design, occupying minimal space and facilitating easy installation and arrangement.

Double stage Roots Blower Specification

1.All models of MTRR series

MTRRB-100 MTRRD-125 MTRRD-130 MTRRD-150 MTRRE-150 MTRRE-190 MTRRE-200 MTRRE-250 MTRRE-300 MTRRF-250 MTRRF-295 MTRRF-300 MTRRF-350 MTRRF-395 MTRRF-400 MTRRG-450 MTRRG-500

Or in customer’s indication range

2.Differential pressure scope

98—196kPa

3.Air capacity scope

0.61—428m3/min

4.Power of the motor

5.5—1000kW

5.Necessary standard accessories(common type)

Discharge connection pipe;1st stage blower;2nd stage blower;middle cooler and its connecting pipe;baseframe;Anchor bolts;elastic joint;check valve;deflating valve;pressure gauge;Suction silencer ; discharge silencer(with air filter);gear oil,etc

Double stage roots blower as an air conveying device, its characteristics mainly include the following aspects:

1.Through two-stage compression, it is possible to achieve higher exhaust pressure at a lower pressure ratio, making it suitable for industrial applications requiring higher air pressure.

2.The unique design of the Roots blower ensures continuous, pulse-free gas flow, maintaining stable flow rates under various operating conditions.

3.Due to the adoption of a simple mechanical structure and fewer moving parts, it experiences less wear during operation, requires lower maintenance, and enhances the equipment’s reliability and service life.

4.Compared to single-stage fans, the two-stage series design achieves the same air pressure with lower rotational speed, thereby reducing energy consumption and noise emissions, meeting modern industrial requirements for energy efficiency and environmental protection.

5.Suitable for various industries such as wastewater treatment, cement production, pneumatic conveying, chemical processing, and grain processing, providing stable gas delivery and pressure control for production processes in these sectors.

6.Despite being a dual-stage design, the overall structure remains compact through optimized design, occupying minimal space and facilitating easy installation and arrangement.