Mechanical Vapor Recompression (MVR)

Mechanical Vapor Recompression (MVR) technology, with its superior energy efficiency, mild evaporation conditions, and strong support for “zero discharge” of industrial wastewater, is becoming the preferred evaporation solution for industries such as food, pharmaceuticals, chemicals, lithium batteries, and coal chemicals.

This article will comprehensively analyze the core advantages, applicable scenarios, and working principles of MVR technology to help you determine if it suits your production needs.

What is MVR technology?

MVR (Mechanical Vapor Recompression) is a highly efficient evaporation process that recovers and utilizes the heat energy of secondary steam through a compressor. The system pressurizes and heats the low-temperature, low-pressure secondary steam generated during evaporation, then returns it to the evaporator as a heat source, achieving a closed-loop energy cycle.

Unlike traditional multi-effect evaporators that rely on external fresh steam, MVR systems only require electricity to drive the compressor to complete the entire evaporation process, significantly reducing energy consumption.

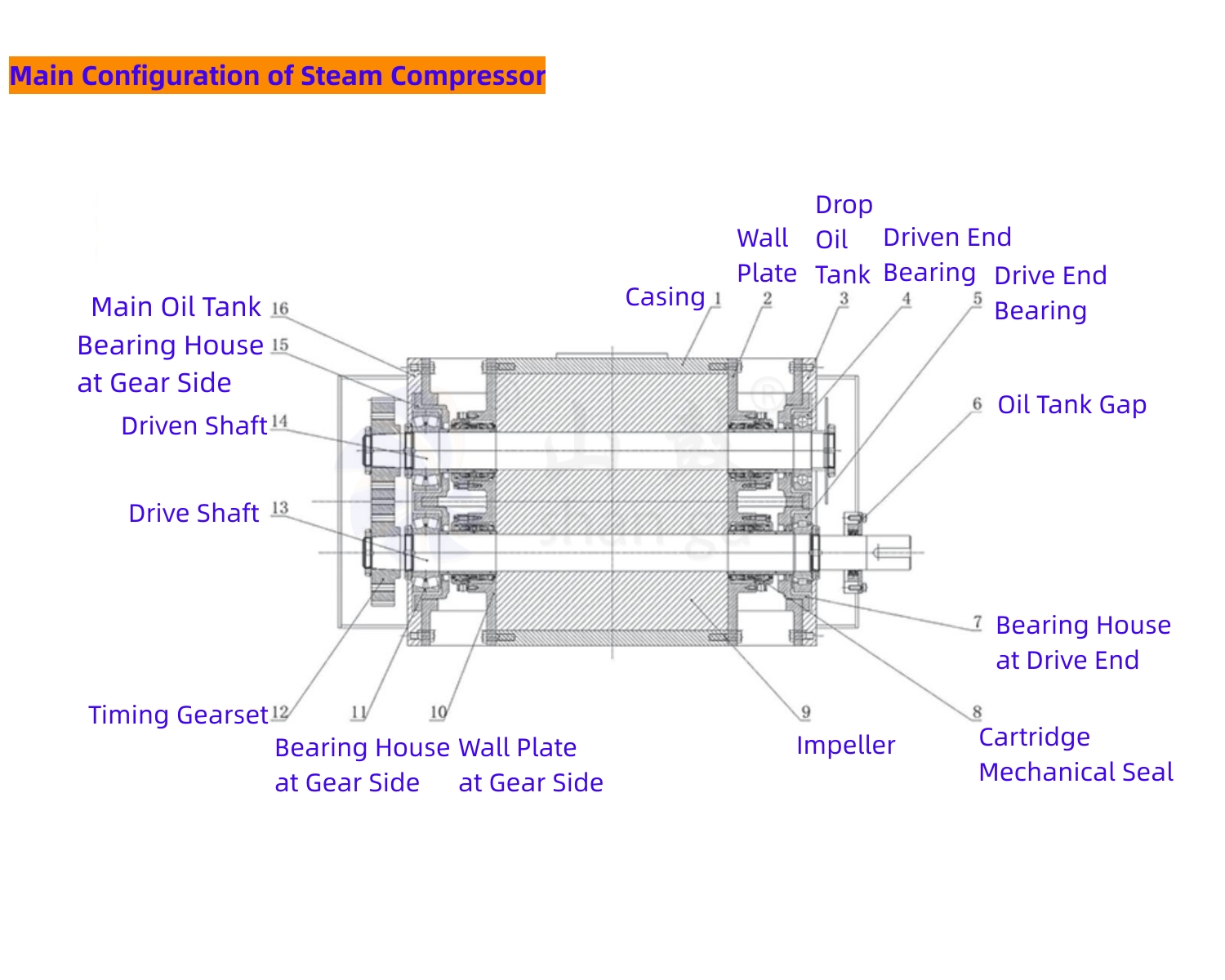

MVR Core Technology: Working Principle of a Roots MVR Steam Compressor

The core of an MVR system is a steam compressor. Roots compressors are widely used in low to medium pressure differential conditions due to their simple structure, stabiele operasie, en gerieflike instandhouding.

How does a Roots steam compressor(Mechanical Vapor Recompression(MVR)) work?

It adopts a dual-rotor parallel structure, with two impellers driven by synchronous gears, rotating in opposite directions at the same speed.

A small gap (usually sealed by spray water) is left between the impeller and the casing and wall plates to avoid metal-to-metal contact.

The inlet and outlet ports are not directly connected, forming a closed “basic volume.”

When the basic volume rotates to the outlet port, the high-pressure steam instantly flows back to equalize the pressure, achieving positive displacement compression.

An initial pressure differential environment needs to be provided by the MVR system; once established, operation is extremely stable and reliable.

Let wel: In addition to Roots MVR Steam compressors, centrifugal compressors are also commonly used in high-flow, high-pressure-ratio scenarios; the appropriate type can be selected based on project requirements.

Mechanical Vapor Recompression (MVR) Configuration

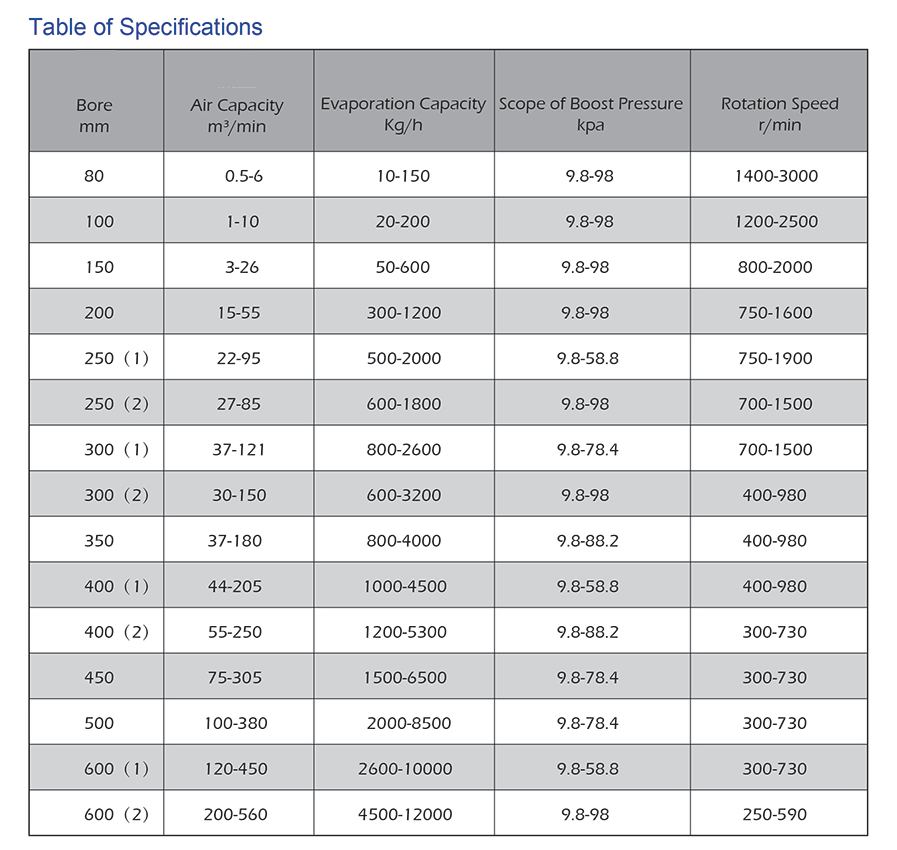

Mechanical Vapor Recompression (MVR) Spesifikasie:

Remark:

- The flow rate calculations in the table are based on a pressure increase of 58.8 kPa and a compressor inlet steam temperature of 85°C. The evaporation rate is also calculated using these parameters.

- The evaporation rate and other parameters in the table are for reference only. For specific parameters, please contact our sales representative to inquire about more detailed compressor specifications.

Typical Application Scenarios of Mechanical Vapor Recompression(MVR) Technology

| Industry | Application Direction |

| Food & Beverage | Whey Concentration, Fruit Juice Concentration, Syrup Evaporation |

| Biopharmaceuticals | Antibiotic Concentration, Traditional Chinese Medicine Extracts, Amino Acid Purification |

| Chemicals/Lithium Battery | Lithium Hydroxide/Lithium Carbonate Mother Liquor Recovery, NMP Solvent Regeneration |

| Environmental Engineering | Zero Discharge (ZLD) of High-Salinity Wastewater, Landfill Leachate Treatment |

| Coal Chemicals | Desulfurization Wastewater, Gasification Ash Water Concentration and Crystallization |

MVR – The High-Efficiency Evaporation Engine for the Green Manufacturing Era

MVR (Megavapor Recompression) technology is not only a powerful tool for energy conservation and emission reduction, but also a key support for enterprises to achieve sustainable development, compliant operation, and resource recycling. With the optimization of electricity costs and the advancement of equipment localization, the economic threshold for MVR continues to decrease, and its application prospects are becoming increasingly broad.

If you are looking for low-energy consumption, low-maintenance, and highly automated evaporation or wastewater treatment solutions, MVR technology is worth in-depth evaluation.

How does a Roots steam compressor(Mechanical Vapor Recompression(MVR)) work?

It adopts a dual-rotor parallel structure, with two impellers driven by synchronous gears, rotating in opposite directions at the same speed.

A small gap (usually sealed by spray water) is left between the impeller and the casing and wall plates to avoid metal-to-metal contact.

The inlet and outlet ports are not directly connected, forming a closed “basic volume.”

When the basic volume rotates to the outlet port, the high-pressure steam instantly flows back to equalize the pressure, achieving positive displacement compression.

An initial pressure differential environment needs to be provided by the MVR system; once established, operation is extremely stable and reliable.

Let wel: In addition to Roots MVR Steam compressors, centrifugal compressors are also commonly used in high-flow, high-pressure-ratio scenarios; the appropriate type can be selected based on project requirements.